Electric motors are integral to many aspects of daily life. They run home appliances, factory gear, and large machinery. Still, many of us rarely look inside them. One hidden aspect, electric motor laminations, has a huge impact on how well these motors work.

Laminations, made of thin steel sheets, make motors more efficient by reducing extra heat and energy loss. Whether you see a big industrial unit or a home mixer, these little sheets often decide how long and how smoothly the motor performs.

Motor designers put a lot of thought into these laminations. They look at factors like thickness, material grade, and how the sheets fit together. Once they do that, they can reduce power wastage and overheating. This setup works for many types of motors, from simple devices in your kitchen to large-scale systems in factories. A three-phase motor, for example, relies on precise laminations for stable power output and a longer lifespan.

Different Types of Electric Motor Laminations

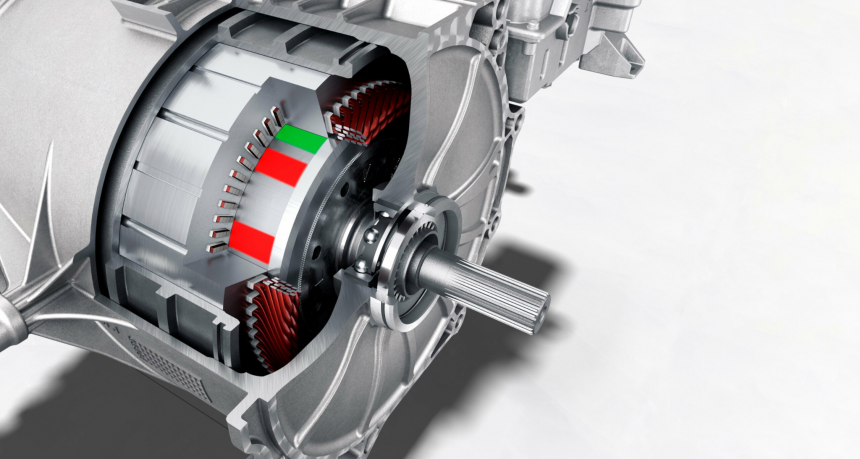

Laminations change based on the motor’s design. Some rotors get wound wires, while others have cast conductors. Stators also differ depending on the application. For instance, smaller motors might only need limited pole counts, while bigger industrial ones might have multiple poles. Each lamination stack must support the magnetic field without creating excess drag.

Wound rotor laminations, for example, are common in heavy-duty settings that need strong control over speed and torque. Die-cast rotors, on the other hand, focus on durability and energy savings. Stator stack laminations hold the windings in place and direct magnetic fields for the motor’s turning force. Brushless DC motors—popular in electric vehicles—need carefully designed sheets that keep heat levels manageable at high speeds.

Key Design Considerations

Thickness matters. Thin sheets are more effective against eddy currents but they can make production a bit pricier. Thicker sheets cost less to make yet can result in higher losses. Material quality also plays a key role. Many manufacturers use silicon steel because it strikes a balance between cost, durability, and performance. Some premium tailor these laminations to exact diameter and length requirements, so each client gets an ideal match for their motor design.

Assembly methods vary, too. In wound rotor designs, the lamination stack might have openings where the winding can pass through, allowing external resistances to be connected. These additions help manage high starting torque or the need for speed control. In other motors, laminations may come with built-in ribs or notches that hold rotor bars in place.

Good lamination design might include vents that allow the motor to cool faster. This small tweak prevents localised heating and improves efficiency. These steps sound minor but often help the motor meet user demands without high maintenance costs later.

Comparing Common Lamination Types

| Lamination Type | Typical Use | Main Advantage |

| Wound Rotor | Mining equipment, heavy machines | Strong torque control |

| Stator Stack | Induction motors, various generators | Reduced eddy current and stable output |

| Die-Cast Rotor | High-performance three-phase motor | Durable and energy-saving |

| BLDC Motor Lamination | Electric vehicles, automation | High speed with lower overheating |

Steps to Get the Most Out of Laminations

You can adopt a few best practices if you want a motor that runs better. These points look simple, but they often solve many real-world issues:

- Pick the Right Material: Silicon steel is a standard choice, but higher grades or blends might suit tough environments.

- Test Early and Often: Check for eddy current losses and see if the lamination stack holds up to high temperatures.

- Inspect Core Assembly: Ensure parts fit closely together. Gaps can compromise the magnetic path and reduce efficiency.

Once a user follows these steps, they often see motors running cooler, lasting longer, and consuming less power. The total cost of ownership goes down, so spending a bit more on quality pays off in the long run.

Where Expertise Makes a Difference

Making good laminations requires more than just machines. It needs a team that understands metallurgy, electrical design, and mechanical assembly. Some facilities have in-house labs for testing hardness, chemical composition, and overall structural integrity. Others rely on third-party certifications for confidence. Leading companies like Godrej Enterprises Group have been known to set high standards in these areas.

Special orders might include custom rotor or stator stacks built for unique applications. You can find stator stacks up to 1000 mm in diameter or die-cast rotors that reduce energy use. Brushless DC motors use specialised laminations to cut down on noise and heat. That level of custom work comes in handy if you operate heavy machinery or a sensitive setup where small inefficiencies add up.

Conclusion

If you’re looking to keep your motor running smoothly, understanding its lamination design is important. This step forms the heart of the system, whether it’s an induction motor in your workshop or a generator that powers a massive plant. Paying attention to the core sheets and how they’re stacked can help prevent trouble later. Many users choose high-grade materials and expert assembly to ensure a cooler, longer-lasting motor that requires fewer repairs.